Intelligent Manufacturing

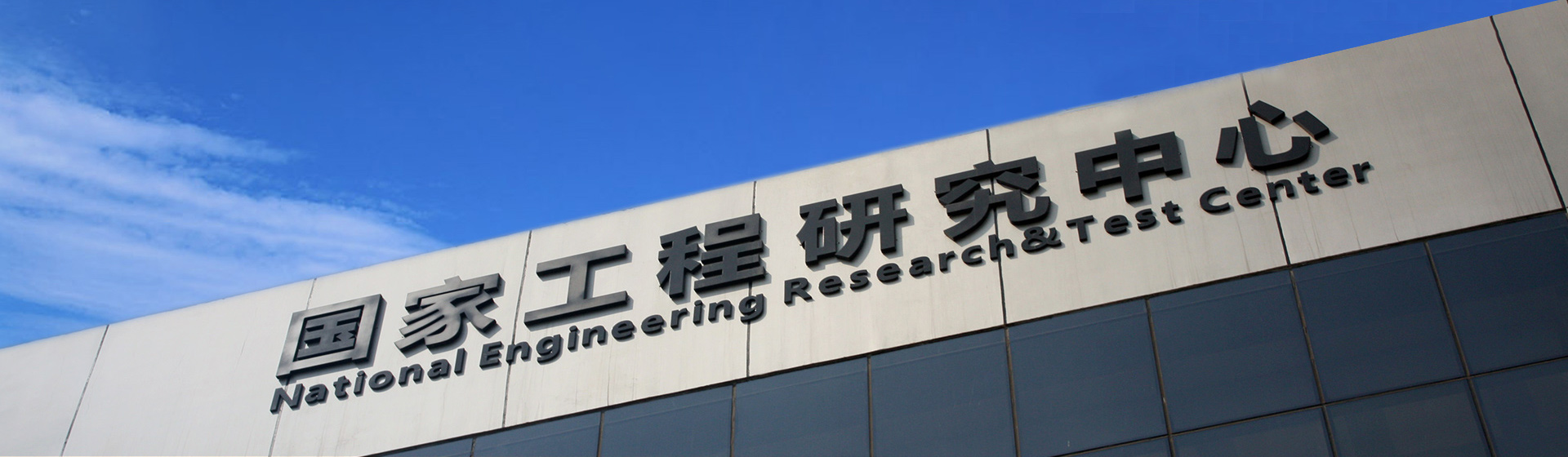

Since its inception, CORUN has adhered to the core management philosophy of “Lean Manufacturing, Quality First”, consistently maintaining high standards of quality management. In recent years, we have comprehensively promoted the upgrade from lean manufacturing to intelligent manufacturing, integrating the technology concept of Industry 4.0 and striving to build intelligent manufacturing capabilities for power batteries. In 2014, our subsidiary Hunan CPEV received support from the Ministry of Industry and Information Technology’s “Industrial Base Strengthening Project” and successfully passed the authorities’ inspection in 2016. In 2015, Hunan CPEV was recognized as one of the first batch of “Smart Manufacturing Demonstration Enterprises in Hunan Province”. In 2017, Hunan CPEV received support from the Ministry of Industry and Information Technology’s “Integrated Standardization and New Model Application Project for Smart Manufacturing”. The implementation of the “Industrial Base Strengthening Project” and the “Integrated Standardization and New Model Application Project for Smart Manufacturing” significantly enhanced Hunan CPEV’s independent innovation and corporate competitiveness, fulfilling emerging market demands and enabling deeper participation in the high-end division of labor within the global power battery industry. In 2021, CORUN was elected as the Chairman Unit of the Intelligent Manufacturing Professional Committee, China Battery Industry Association.

1. Effectively addressing common issues in the production process of the power battery industry

Intelligent manufacturing will form integrated application modes for the research and development, manufacturing, operation, and service of power batteries; application modes for intelligent production line control, monitoring, testing, and quality management technologies; and deeply integrate traditional lean manufacturing modes with advanced intelligent manufacturing modes, incorporating lean production concepts into information systems, embedded software, and intelligent equipment to achieve timely, appropriate, low-cost, high-quality, and short-lead-time production, thereby addressing common issues in the power battery industry such as low production efficiency, high production costs, and high product defect rates. This provides a reference for other power battery enterprises and core automotive parts companies.

2. Driving the core component industry of energy-saving and new-energy vehicles.

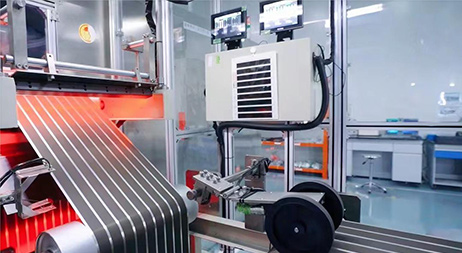

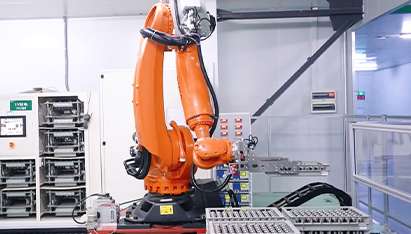

Since the implementation of intelligent manufacturing, the Company has developed core digital equipment with independent intellectual property rights, optimizing traditional manufacturing processes; adopted high-precision, high-digitization online testing equipment and established an advanced quality management system; optimized manufacturing processes through data production, acquisition, and analysis during manufacturing; and achieved collaborative manufacturing among upstream and downstream enterprises in the industry chain through the “Internet +” production model, actively driving the industrial upgrading and new technology application of the core component industry of energy-saving and new energy vehicles.

3. Replicable achievements, easily accelerating industry promotion.

The achievements mainly include standardized information software, intelligent inspection and assembly equipment, intelligent data acquisition systems, standardized equipment communication services, etc., which are highly versatile within the power battery industry, easy to replicate, and can be rapidly promoted within the industry, swiftly driving the intelligent upgrading of the entire power battery industry.

1. Effectively addressing common issues in the production process of the power battery industry

Intelligent manufacturing will form integrated application modes for the research and development, manufacturing, operation, and service of power batteries; application modes for intelligent production line control, monitoring, testing, and quality management technologies; and deeply integrate traditional lean manufacturing modes with advanced intelligent manufacturing modes, incorporating lean production concepts into information systems, embedded software, and intelligent equipment to achieve timely, appropriate, low-cost, high-quality, and short-lead-time production, thereby addressing common issues in the power battery industry such as low production efficiency, high production costs, and high product defect rates. This provides a reference for other power battery enterprises and core automotive parts companies.

2. Driving the core component industry of energy-saving and new-energy vehicles.

Since the implementation of intelligent manufacturing, the Company has developed core digital equipment with independent intellectual property rights, optimizing traditional manufacturing processes; adopted high-precision, high-digitization online testing equipment and established an advanced quality management system; optimized manufacturing processes through data production, acquisition, and analysis during manufacturing; and achieved collaborative manufacturing among upstream and downstream enterprises in the industry chain through the “Internet +” production model, actively driving the industrial upgrading and new technology application of the core component industry of energy-saving and new energy vehicles.

3. Replicable achievements, easily accelerating industry promotion.

The achievements mainly include standardized information software, intelligent inspection and assembly equipment, intelligent data acquisition systems, standardized equipment communication services, etc., which are highly versatile within the power battery industry, easy to replicate, and can be rapidly promoted within the industry, swiftly driving the intelligent upgrading of the entire power battery industry.